Welcome to Newmax Engineers

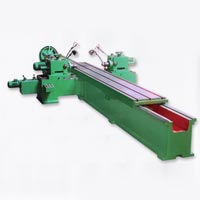

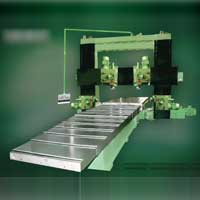

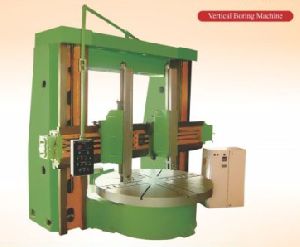

Established in the year 1958, NEWMAX is a renowned Manufacturer, Exporter and Supplier of Lathe Machine, Boring Machine, Planner/Plano Miller, Shaping Machine, Drilling Machine, Milling / Slotting Machines, Power Press Machines, Power Hacksaw /.. Read More

-

Proprietor

Mr. Gopal Krishan Aggarwal

-

Year of Establishment

1958

-

Primary Business

Manufacturer

-

Number of Employees

21 - 50

-

Annual Turnover

Rs. 2.5 to 5 Crore Approx.