Listing ID #256051

Company Information

Ask for more detail from the seller

Contact SupplierBlade type diamond dressers are basically conceived from the multi - point wheel dressing concept as an extension to the areas with a stringent control demand on quality & economy. Blade type dressers are best suitable for forming (angular/radius) of grinding wheels. On heavy-duty grinders, especially center less grinders, often the demands are high both on quality and productivity.

features of wheel dressing (blade type diamond dressers):

uniform dressing over the full length of wheelproper abrasive glaze-free surface on the wheelwheel edges free of broken edgesat the same time, from the economic point of view, the dresser becomes expensive when properly designed to meet all the three requirements. However, a combination dresser has been conceived to combine quality with economy.

specifications

diamonds are hand set with a specific diamond pattern to provide consistency throughout tool life for uniform wheel conditioningprecision dressingdressing difficult profiles and straight applicationslong lifeno resetting

common applications

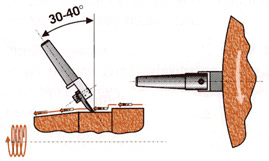

centre less grinding (plain), cylindrical grinding with wheels (500 mm, and above in dia.), surface grinding (tos, blohm and other heavy duty large machines.)optimized conditions of the grinding wheelmodern grinding technology has facilities to optimize a grinding process to the barest minimum operational cost-provided, the very starting point of the operation, namely dressing, is optimized

proper dressing demands the following conditions on the grinding wheel surface

a pure abrasive action - no "rubbing" actionproper fracture of individual grains to expose maximum abrasive area for grindingminimum "filling" of bonding cavities on the wheel surface to minimize friction during grinding operationminimum "grain pullout"