Listing ID #4183857

Company Information

Ask for more detail from the seller

Contact SupplierButterfly Valves are having variety of applications in Process Industries, Water Treatment, Sewage Plants, Power, Petrochemicals, Steel Plants and allied industries in a very large quantity. All type of Butterfly Valves is available with control type lever, Manual Gear, Pneumatic and Electric Actuators. We offer Butterfly Valves in cryogenic type of design.

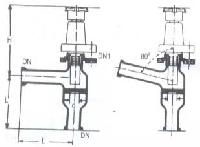

A Butterfly Valve is a flow regulating disc valve. According to the BVAA, a Butterfly Valve is “a Valve in which the obturator rotates about an axis at right angles to the direction of flow and, in the open position flow passes around the obturator.” Butterfly Valves operate similar to Ball Valves in their 90-degree rotation and allow for quick shutoff.

Butterfly Valves have gained popularity over the years due to their thin profile between flanges, making them lighter in weight and creating a smaller install footprint. This compact design also usually makes the initial cost for these Valves lower when compared to other Valve designs. There are different types of Butterfly Valves and each type has unique design features and applications. Each type is defined by the orientation of the stem to the disc and the seating angle that the disc closes on.

Concentric Disc Butterfly Valve is widely used in water treatment and other industries, because of its advantages: light weight, small size and easy for installation, low cost. The most basic butterfly valve design is commonly called a concentric or resilient-seated butterfly valve. In this type of valve, the stem is centered in the middle of the valve disc, which is centered in the pipe bore. This valve typically has a rubber (or resilient) seat and relies on the disc having a high level of contact with the seat to affect a seal.

The valves are provided with integrally moulded elastomer body liner for perfect seating and complete isolation of body material from fluid media. No gaskets are required as the body liner effects a perfect seal between the valve body and the mating pipe flanges. Sealing is provided by preloaded contact between flat seat surface and rounded polished disc hub area. Valves are designed and manufactured as per BS 5155/API 609/AWWA C504. The valves are available for all fluid service requirements with suitable body liner, disc material combinations for up to 210o deg.C in PN6, PN 10, PN 16, ANSI 125 & 150 rating. Other special materials and design are also provided according to the customer’s requirement.

In a single-offset Butterfly valve, the stem is located behind the disc. There are few, if any, valves of this type left on the market today due to the development of the double-offset, or high- performance, valve. The single-offset of the stem causes the disc to contact the seat with three to four degrees left to travel with the idea that less seat contact will enable the valve to last longer.

Offset Disc Butterfly valves are designed to withstand higher pressure than the concentric disc design. In this design, the disc remains in contact with the seat only during closing of the valve. Due to this design, the seat lasts for longer period than in Concentric Disc design. Offset disc butterfly valves are suitable to replace the sealing element as and when required.

With the triple offset butterfly valve there are three offsets. Two are placed in a similar position to the double offset butterfly valve, while the third offset is the geometry of the seating surface, creating a type of cone shape of the disc and seat. This cone angle, along with the two eccentric shaft offsets, allows the disc to seal against the seat with no friction.

Triple offsets are generally used in applications similar to gate valves, where a metal seat is required, and tight shutoff and/or quarter turn actuation is desired. Applications like high pressure steam (over 150 PSI), superheated- steam, high temperature gases and oils, high temperature applications are good for this type of valve because a metal seat is required over a soft seat.

The triple offset valve is used in similar industries as the double offset butterfly valve, but in more demanding applications.