Company Information

Ask for more detail from the seller

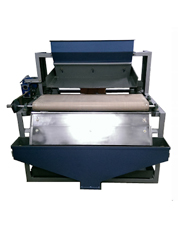

Contact SupplierOperating Method

A Short conveyor belt envelopes the Magnetic Roll and tensioning the Ideal Roll. An efficient Feeder discharges material on the Belt. The Ferro Magnetic and Para-magnetic particles adhere to the Belt while the nonmagnetic particles flow freely off the end of the Conveyor.

Features

Magnetic Rolls are available in 65, 75 & 100 mm dia and widths upto1200mm . There are three different Magnetic Strengths i. e. 8000 Gauss, 20,000 Gauss and 22,000 Gauss. The Roll is driven by a 0.5 HP, variable speed DC/AC geared Motor drive adjustable from 0 to 100 RPM. For the purpose of Feeding, Vibratory Feeder with Control is provided. The Machine is provided with Abrasion resistant endless conveyor Belts of 0.8mm thickness.

Applications

Nirmal Machines are most suitable for various types of Industrial Minerals applications i. e. Abrasive, Refractory and Ceramic Raw Material beatification, Alumina, Silica, Carbide, Magnetic, Quartzite, etc. Glass Raw Materials, Clean Silica Sand, quartz, Feldspar, Dolomite etc., Ultra High Purity Quartz Cleaning, Graphite Upgrading, Manganese Orebenification, Bauxite Upgrading, Diamond ore benification, Selective Separation of Garnet / Ilmenite/Rutile, Zircon, Benification of Iron ore, Recovery of Metals from Slag, Removal of Ferro Silicate from Limestone, Megnesite etc.