Listing ID #4091770

Company Information

Ask for more detail from the seller

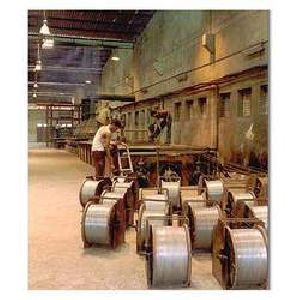

Contact SupplierAssomac group provides its customers the most modern, cost effective, efficient and fast operating lines for hot dip galvanized wire plant. We provide equipment right from drawing lines flattening mills, complete galvanizing lines with vertical drop coilers, horizontal side winder take ups or strip take ups.

By excellence in design, engineering, manufacturing and service we are able to offer most relevant technology for Galvanizing of High Carbon and Low Carbon Steel Wires.

Assomac has become the pioneers in supply of turnkey projects for the wire industry; we will maintain this position trough reliable equipment and service to our customer's world wide.

The plant consists of the following :