Listing ID #6322059

Company Information

Ask for more detail from the seller

Contact SupplierMilk Plant Falling Film Evaporators are widely used in the Milk Plants and Dairy Plant industry. We manufacture highly efficient and durable Multi-Effect Falling Film Evaporators ( Milk Plant Falling Film Evaporators). Able Engineering manufacture Milk Plant Falling film evaporator according to required effects and capacity. Able Engineering is the leading manufacturer of Milk Plant Falling Film Evaporators & complete Dairy and Milk Processing Plant and Plant Machinery Manufacturer.

How it works

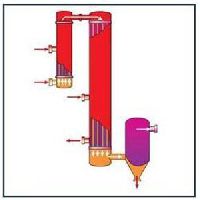

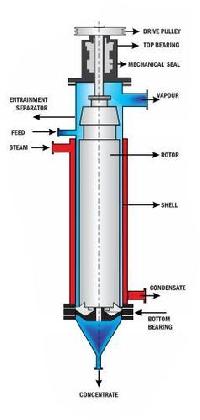

The evaporation process is used to concentrate whole milk, skim milk, whey, whey protein concentrate and permeate from membrane filtration modules. Water is evaporated through indirect heating. Product and heating medium (steam) are kept separate from one another by using a sheet of special steel. The heat released during the condensing of the steam is transferred to the product via the partition. It takes a large amount of energy to boil off water from a solution. This energy is often supplied as steam. To reduce this amount of steam needed, the evaporator is normally designed as a multiple-effect evaporator.

Two or more effects operate at progressively lower vacuums and thus with progressively lower boiling points. In such an arrangement, the vapor produced in the first effect can be used as a heating medium in the next effect. The result is that the amount of steam needed is approximately equal to the total amount of water evaporated, divided by the number of effects.

Some of the Products being processed on Milk Plant Falling Film Evaporator.