Listing ID #3792973

Company Information

Ask for more detail from the seller

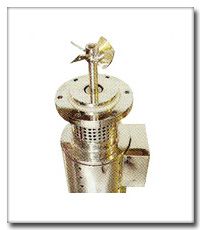

Contact SupplierIPEC is one of the leading manufacturer, supplier & Exporter of Liquid Manufacturing Plant in India. The Liquid Manufacturing Plants are ideal tools for the pharmaceutical industry for the production of Oral Liquids.

It is specially designed to take care of two critical factors which directly affect the quality of the Liquids. Minimum manual handling of Liquid. Effective cleanness during manufacturing. Capacity ranges from 50 L to 20,000 L. Needless to say, it also provides the benefits of the effective manpower utilization.

IPEC is quality manufacturer, exporter & supplier of Liquid Manufacturing Plant in Gujarat, India.

Liquid Manufacturing Plant consists:

Salient Features of Liquid Plant: