Listing ID #1256892

Company Information

Ask for more detail from the seller

Contact SupplierBuy corrosion resistant and highly durable Lead Refining Kettles from us as per requirements. We offer them in varied designs, styles and sizes to cater to varied demands of buyers. Our company is ranked among responsive and responsible Manufacturers, Exporters and Suppliers of a comprehensive assortment of Lead Refining Kettles. They function optimally and guarantee long service life.

Known For

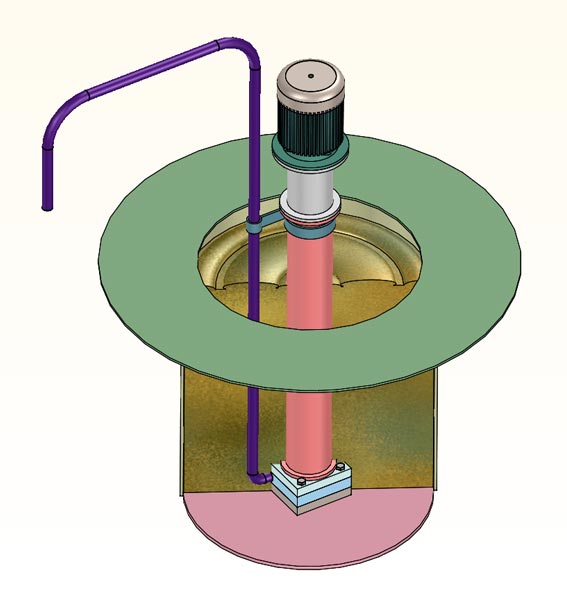

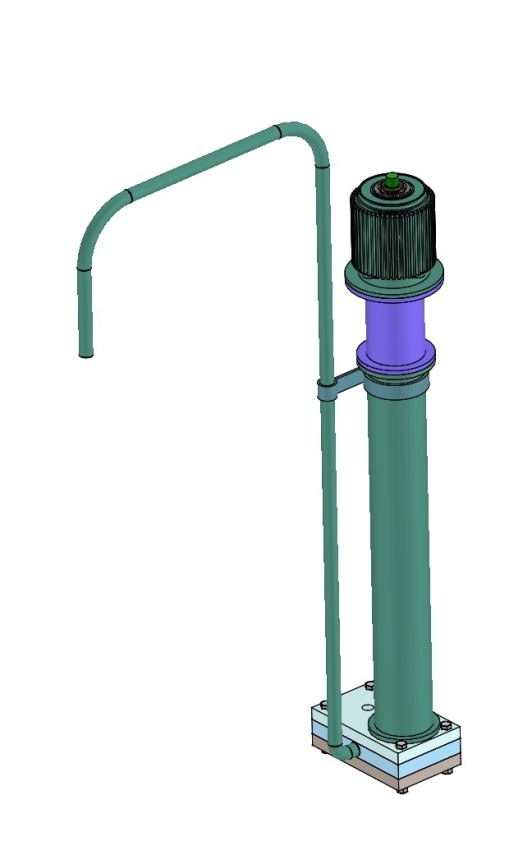

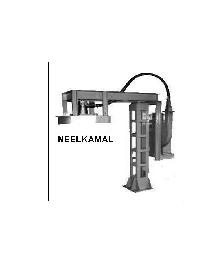

Stirrer and how it function? :

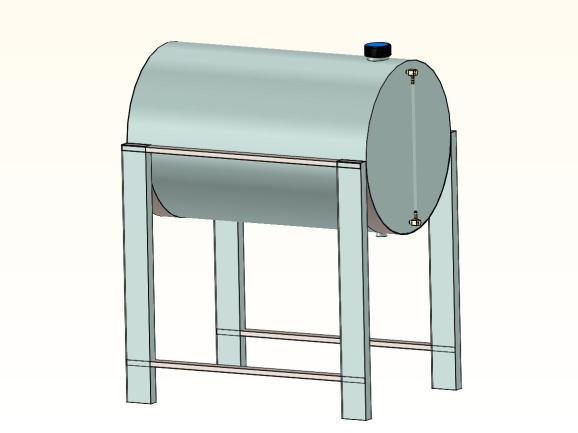

Fluid-O-Matic Alloying Pot :

Fluid-O-Matic Refining Pot

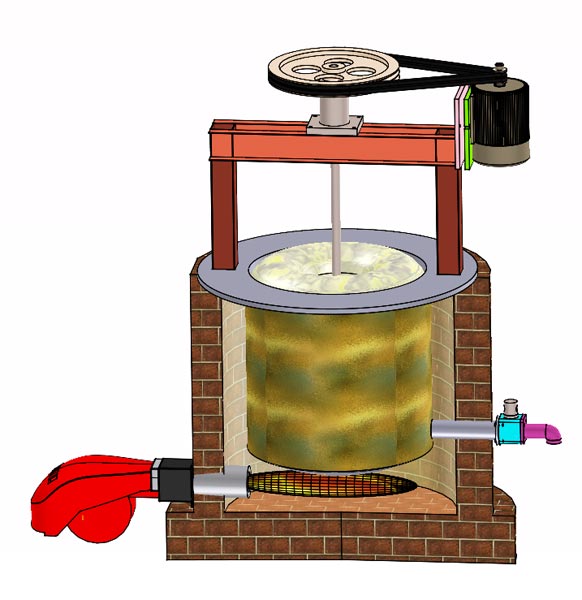

Standard Refining Kettle - It Consistes of following :

Burner for Refining Kettle :

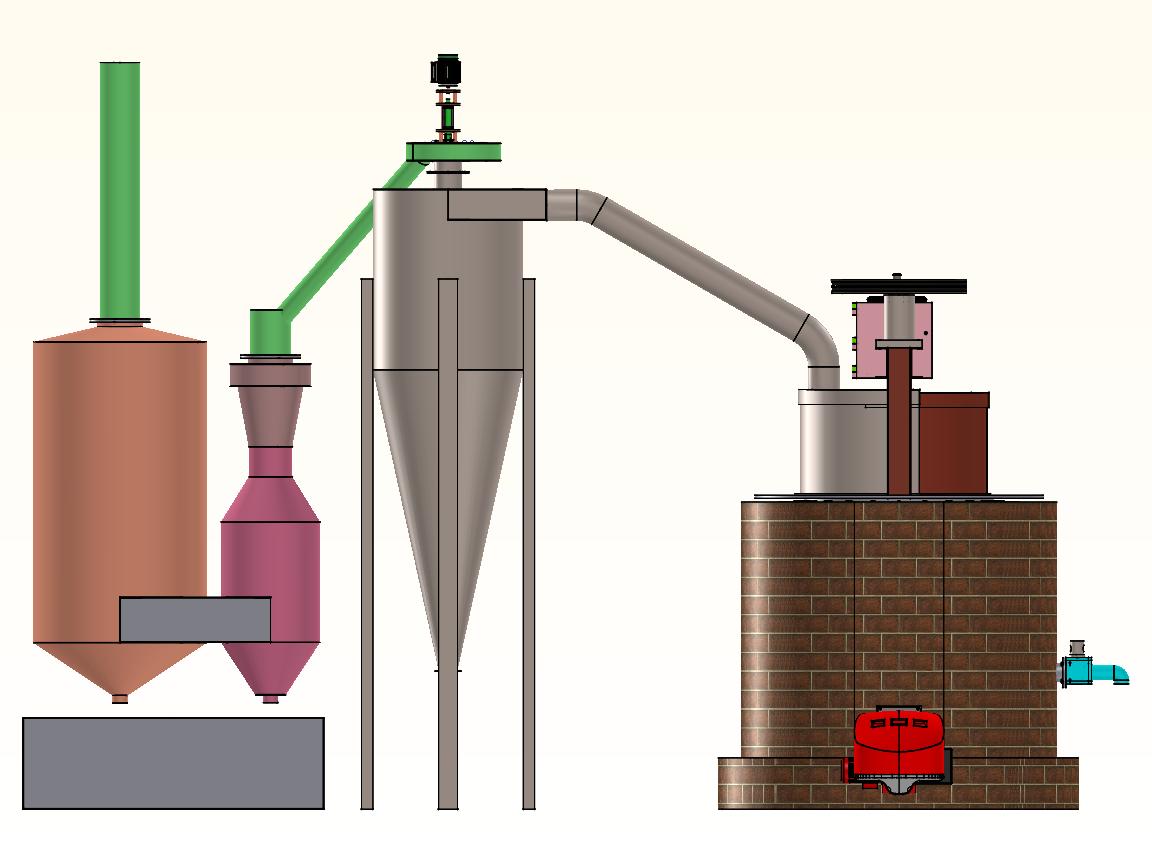

Emmision from Refining Process :

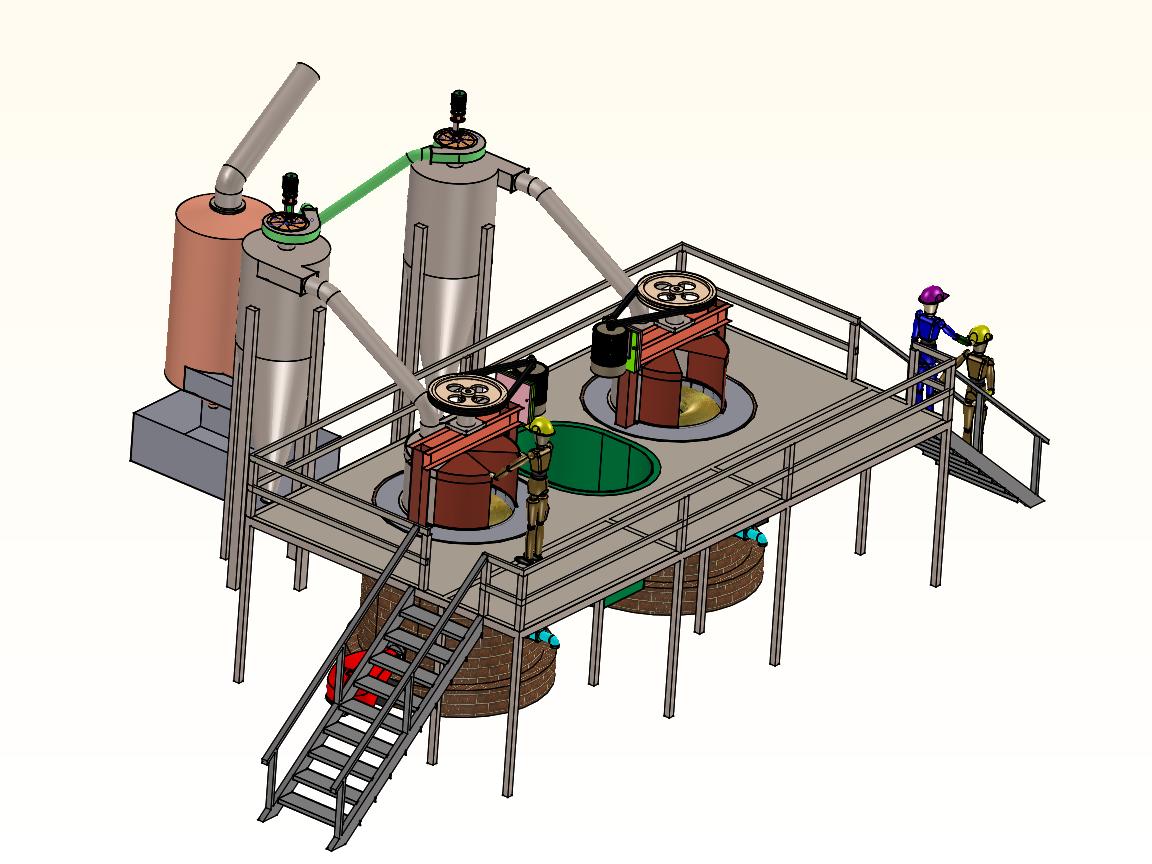

Alloying and Refining Plant with following :