Listing ID #256049

Company Information

Ask for more detail from the seller

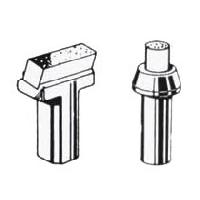

Contact SupplierDiamond grit impregnated dressers have been developed from multi-point dressers. In contrast to the latter they are manufactured from crushed diamond grit rather than a larger number of small natural diamonds. Multi point diamond dressers contain large number of natural diamond particles. These are uniformly distributed in carbide or tungsten matrix in random pattern. The advantages of the diamond impregnated dresser lie in its exceptional sharpness, which results from sharp edges and points of the broken diamond grit. Important advantages are higher dressing feed rates and in feeds as well as the possibility to dress almost all grinding wheel grain sizes from course to fine. As robust dressing tools multi point dressers are easy to handle and often replace the diamond single point dresser. Multi point diamond dressers can only be used for flat dressing of periphery and lateral faces. It is suitable for hard, medium and fine surface like dressing resin, vitreous and rubber bond, fine grit and even so called "grit free" grinding wheels, as well as boron carbide grinding wheels, dressing single profile threaded and v-profile grinding wheels, for general dressing operations on centre less, cylindrical and surface grinding machines. Diamond grit impregnated dressers demand greater care in selecting the correct dresser for a given application. The bond and diamond grit size used are both variable according to the type of grinding wheels to be dressed. The size of the diamond grit particles should be matched to the grit size of the grinding wheel.

guide lines to improve the life of the multi point diamond dressing tool

a plentiful supply of coolant should be provided both before and during dressing to prolong dresser lifethere must be a perfect fit between the holder of the diamond dressing tool and the dressing device. Otherwise dimensionally stable dressing with a true profile is not possiblethe angle of diamond grit impregnated cutting face of the dresser should be set at: 90â° to the grinding wheel to be dressedcooling improves the dressing results considerably and is mandatory for exacting dressing requirements. A strong and continuous flow of cooling medium must be fed to the contact zone prior to the beginning of the dressing processthe feed rates used may be double of those used with single-point diamond dresserskindly specify the bond at the time of orderingbz = moderate force is permissible for dressing fine-grain grinding wheelsh = tungsten carbide bond ( sic grinding wheels )w = tungsten bond (corundum grinding wheels)