Company Information

Ask for more detail from the seller

Contact SupplierApplication: Online partial discharge measurements detect failures in the stator winding insulation in operation. Online partial discharge measurements can be taken either periodically with a portable partial discharge analyzer or continuously with a permanently installed monitoring system. Partial discharge monitoring is applicable on large hydro-generators or on turbo-generators.

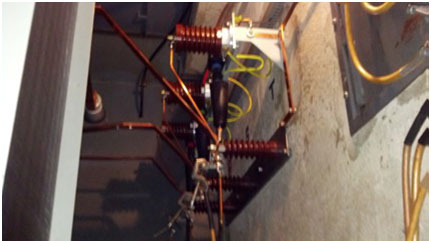

TYPICAL FAULTS DETECTIONSTypical Installation: Partial discharge couplers installed on each generator/ motor phase exit.

Shaft and Bearing Vibration for Hydro GeneratorApplication: Shaft and bearing vibration monitors the vibration amplitude to detect wear of bearings, shaft imbalance and misalignment. The shaft and bearing vibration monitoring is specified in the ISO-7919 and ISO-10816 norms respectively. Plain bearings deterioration and failures can be detected using condition monitoring tools such as shaft center path (orbits) and shaft centerline. Shaft and bearing vibration are applicable on any rotating machines such as hydro turbines, gas turbines, steam turbines, pumps, fans, cooling fan towers.

TYPICAL FAULTS DETECTIONSTypical installation: 2 proximity probes or absolute vibration sensors installed at 90° apart located in the radial direction.