Listing ID #881776

Company Information

Ask for more detail from the seller

Contact SupplierYPM Fluid Bed Dryer capacity was ranging from 30 / 60 / 120 / 150 / 200 Kgs., with Steam heating / electrical heating & thermal heating facility.

Electrically / Steam & Thermic Fluid Heated in which general structure, made out of mild steel & painted in Standard Model & made out of S.S.304 quality material & polished to the matt finished in GMP Model, but contact parts i.e. Product Container and Retarding Chamber, are made out of S.S.304 / S.S. 316 quality material, with Non-Flameproof blower motor, (Flameproof motor provided on demand) suitable to dry wet material.

YPM Fluid Bed Dryer is the right combination of an accurate controlled air direction flow with the exact air speed to minimize the pressure drop in the fluid bed, to ensure a perfectly balanced process preventing granule agglomeration and allowing a uniform fast growing of the granule with low and controlled moisture residual.

The process unit is two pieces made of SS-304 / 316 stainless steel. Through mixing of Dry powders, Agglomeration and Drying are carried out in one unit of YPM Fluid Bed Dryer.

Salient Feature : Process Unit

Uniform reproducibility of high quality batches

Easy scale up to higher capacity units

Easy to validate cleaning process

Homogenous granules

Gentle product handling

Pharmaceutical execution for cGMP compliance.

AC inverters for precise air flow controls of the fluidized bed dryer process

Execution for hazardous areas for organic solvent processing

Inflatable seals with interlocking device to control correct bowl position

In house R&D for your product development

Fluid bed granulators available in large variety of capacities

Perfect control of air turbulence in tangential way with very low pressure drop

Uniform distribution of binder solution on each single granule

Fluid bed with the ability to granulate soluble and hygroscopic materials

Fluid bed with the ability to granulate fine particles

A more stable, reliable, repeatable, consistent granulation

Very fast processing time

No clogging of the guns and filters

No product loss and high yield

With the majority of formulations it is possible to avoid the use of the high shear mixer and the sizing mill

Bowl / Product Container

Product bowl is a conical shaped manufactured form SS-304/316 grade stainless steel having stainless steel mesh support along with fine finish air mesh.

The product container Trolley is of Tubular construction made form SS-304 pipe mounted on polypropylene castor wheel (2nos fixed & 2nos. Swivel for maneuverability) which imparts rigidity to carry the product container with the charged load.

The batch loading capacity is always higher in case of “YPM” Fluid Bed dryer, because of better fluidization by varying the frequent shaking of the finger bags. Shaking period vary depending on the nature of products.

Rubber Gasket : A solid ‘D’ shaped food type silicon rubber gasket is provided in the groove of the flanged joint (between the product container and the retarding chamber) to prevent any leakage of air with fines during operation.

Uniform Lifting of Container : Product container is lifted by specially designed arrangement with the help of one centrically fitted pneumatic cylinder which ensures uniform lifting throughout the periphery of the container which ultimately gives uniform upward pressure to the solid ‘D’ shaped Rubber Gasket, thereby preventing any leakage during operation.

Auto Shaking Device : Pneumatic cylinder is used for auto shaking device of the finger bags is mounted on the body and is fitted with a wire rope made out of S.S. 304 guided by pulleys thus rendering the shaking extremely efficient. It also brings down the finger bags to such a level that these can be inspected very easily form the bottom of the retarding chamber. If the shaking is not efficient, the particles will be retained in the finger bags and there will be no proper fluidization resulting in formation of lumps in the products container.

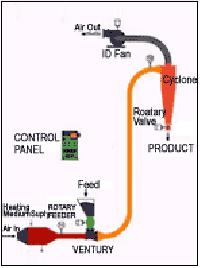

Air Handling Unit : Blower and filter with heating arrangement are housed in the rear chamber . They can also be housed the services zone to avoid sound pollution as well as to avoid interference of the maintenance people in the production zone.

Blower :

Centrifugal type blower fan with dynamically balanced impeller and backward curved blades.

All Stainless steel construction.

Direct coupled non-flameproof electric drive. Anti – vibration mounting and independent sub-support frame.

Air filter

Explosion Vent : As per international practices the equipment is provided with a rapture disc as measures of explosion Vent, Tested at 2 bar pressure, mounted on the side of the dryer.

Earthing Device : A standard designed earthing device spring type is provided with the dryer however intrinsically safe earthing device with low voltage relay is also available.

Electro Pneumatic Control Panel : a free standing steel control panel having the following controls.

Inlet air temperature controller

Exhaust air temperature indicator

Product bowl lifting & lowering valve

Process air Damper regulation

Blower motor, start & stop

Compressed air pressure gauges

Filter bag shaking timer

Solenoid valves etc.