Listing ID #424459

Company Information

Ask for more detail from the seller

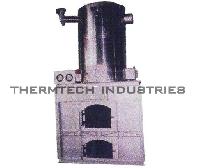

Contact SupplierThe company is engaged in the manufacturing, exporting, and supplying of 3 pass fluid heater all across the globe. For process heating applications, our 3 pass fluid heater can be substituted against steam or electricity instead of pressurized hot water or steam as it uses thermic fluids for heat transfer. The 3 pass fluid heater has simple and closed circuit system and is designed on the coil type once through, forced circulation principle to use hear transfer fluids without the risk of chemical degradation. Temperature up to 300 c can be obtained with an accuracy of +-1% at a low working pressure of 2.5kgcm (aaprox.). construction the internal combustion chamber is used to accommodate concentric helical tube wound coil, (fabricated out of erw) boiler tube as per bs 3059). This coil is placed in a double shell of mild steel construction. This type of design helps in economizing the space and simultaneously ensures optimum rate of heat release. Due to elimination of extensive use of refractory, it permits rapid start up and operational and maintenance flexibility. combustion a fuel atomizing pressure-jet burner fitted with fuel oil nozzle from “monarch (usa) is placed vertically downward for combustion. A dynamically balanced blower fan pushes the combustion air through the annular space between the inner and outer shell, where air is pre-heated for efficient combustion and higher efficiency. The air acts as an effective thermal insulator eliminating the need for conventional insulation. Near the tip of burner, air is swirled through a stainless steel diffuser plate and mixes atomized fuel, which achieves total combustion in the furnace. burner and fuel system fuel pump supplies fuel to pressure jet burner from tank though filter. The burner is fully automatic in operation & switches on and off, as per process heat requirements. instrumentation, control and safety it is a fully automatic 3 pass fluid heater fitted with safety devices like high fluid temperature switch, low level switch in expansion tank, spring valve, high stack temperature switch, flame sensor, low fuel oil temperature switch and circulating pump motor interlock and used instruments from reputed manufacturers like landis & gyr (germany), monarch (usa), danfoss (denmark), larsen & tourbo, siemen, ngef,cromptor1, kirloskar, salzer, finolex, bells, lndfoss, tatat.i.k.s.b. Auro, mcbs overload relay, contractors, safety alarms, temperature controllers, temperature indicator and sequence controller has audio—visual alarms for abnormal working conditions.

technical specifications

detailmodelat – 0.5at – 01at – 02at – 04at – 06at – 10at – 15heat outputkcalhrs500001,00,0002,00,0004,00,0006,00,00010,00,00015,00,000fuel consumption (approx)l.d.okghrs5.711.422.945.768.6114.4171.6h.s.d-5.611.322.54567.6112.7169.1thermal efficiency87% ± 1% 560 hz + 3%, ac – 3 phase, 4 wireelectrical supply415 ± 6% 560 hz + 3%, ac – 3 phase, 4 wirecirculating pump motorhp2.05.07.512.515.020.025.0kw1.53.75.59.411.251518.75fuel pump motorhp♦♦♦♦0.51.01.0burner motorhp 0.51.02.03.05.010.015.0 kw0.370.751.52.23.73.711.0burner controlon-off0-50% on-off 50-100% low-high0-33% on-off 33-100% modulationtotal connected loadkw2.05.08.012.015.023.030.8dry weight (approx.)kg75093013002350300036004100overall dimensions (meters)length width height 1.21.501.591.852.142.403.00.790.841.031.831.902.302.500.792.102.262.803.263.504.30